When one is in college, they experience many new things, including the first, second, and probably the third base—well, not for everybody, maybe? Much to my amusement, I too tried many new things while in college (including the aforementioned), and among them was being a part of a Formula Student team.

Wondering what a Formula Student team is? It’s the ultimate playground for engineering students, where textbook knowledge collides head-on with the challenges of real-world application. This competition, rooted in the principles of the Formula SAE, puts teams through a meticulous inspection process before unleashing their creations in dynamic events. The final judgment encompasses everything from a business plan presentation to cost evaluation, engineering design, and technical inspection.

A designer’s life starts at CAD and ends at Ansys Formula Bharat, India’s rendition of Formula Student, is where meticulously designed cars take centre stage. With 10-20 teams competing in six critical categories, this event is the proving ground for innovation. The judging criteria, spanning both static and dynamic events, create a comprehensive evaluation of the vehicles.

The winning team, accumulating the highest points out of 1000, emerges as the Formula Bharat champion. This prestigious title reflects excellence across design, innovation, business acumen, and on-track performance.

Now, to understand more about the current scenario since I’ve been off-touch for a long time, I visited Team Octane Electric Racing from COEP Technological University. Established in 2011, this team carved a legacy by turbocharging the KTM 390 engine, marking the first team in Asia to achieve this feat. Transitioning To the electric era in 2019 with ‘Alectrona,’ this electric marvel secured the formula Bharat concept award, ushering in a new era of innovation.

Formula Student serves as the foundational base for automotive technology and design, offering aspiring engineers a hands-on playground where theoretical knowledge transforms into tangible innovation. Participants dive into the intricacies of vehicle dynamics, aerodynamics, and powertrain design, refining their skills in the crucible of real-world challenges. This competition mandates a holistic approach, from conceptualizing engineering marvels to managing projects, mirroring the multifaceted demands of the automotive industry.

Formula Student becomes the proving ground where students not only learn to push the limits of technology but also embrace the essence of teamwork, project management, and problem-solving — essential skills that resonate far beyond the racetrack, laying the groundwork for a career as an automotive professional. It is a symbiotic relationship between education and industry, nurturing talent and innovation from the grassroots level.

Now, the next few paragraphs might sound boring as I go on and describe the design and technological innovations of their vehicle, Alectrona 3.0.

The chassis, constructed with AISI 4130 and Al 7075-6, underwent rigorous simulation using tools like Ansys to ensure structural integrity and optimal performance. Composites, including carbon fibre-reinforced polymer (CFRP), are used for the bodywork, and a sandwich composite structure for the impact attenuator. A lot is going on in the design front and its possibilities.

Alectrona 3.0’s drivetrain, featuring a two-stage drive, custom limited-slip differential, and carefully selected gear ratios, reflects a comprehensive understanding of vehicle dynamics. The thermal management system, employing a copper jacket and Al 6061 chill plate, attests to the team’s dedication to maintaining optimal powertrain temperatures. There are even safety circuits as well as data logging equipment on-road, which captures the data for further processing.

The e-powertrain is a 3-phase AC induction motor, connected to a sophisticated battery pack. The lithium-ion battery pack, with 80 cells, powers the electric propulsion. There’s also an integration of a custom battery management system (BMS). For the various fabrication processes, there are so many processes that go into the making of this vehicle, such as welding, cutting, polishing, laser cutting, as well as lathe operations.

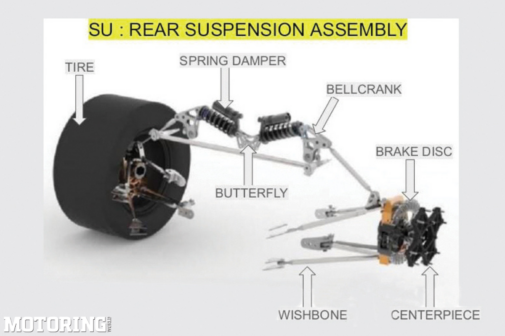

Students delve into the intricacies of Pro-Ackermann Geometry, double-wishbone suspension, and limited-slip differential design, gaining invaluable insights into the dynamics of vehicle performance, including the thermal management of the battery and its components.

In essence, Formula Student acts as a cornerstone for young engineers to master automotive technology and design It provides a hands-on learning experience, converting theoretical knowledge into practical innovation. Beyond the racetrack, it cultivates essential skills such as teamwork, project management, and problem-solving, laying a strong foundation for a successful career in the automotive industry. I would really look forward experience driving it.