Soon after its unveil, the All New Hyundai Creta has already received well over 10,000 bookings. We took a trip to Hyundai’s manufacturing facility in Chennai, Tamil Nadu, to see how the All New Creta is built.

Before production of a new model even begins at the plant, every model goes through four stages of trials. While it is usually a time-consuming process, the time taken for these trials has been reduced significantly thanks to new technology such as digital pre-assembly. Everything in terms of parts and processes is loaded on to computers to figure out how the process and its efficiency can be improved. Therefore, before a car is even put on the physical line, everyone involved in making the car is already aware of what to expect and what to do thanks to the virtual checking of it. Another technology that sees a lot of use is 3D printing. Samples and moulds of different variations are made rapidly to evaluate the best possible option. Finally and most importantly, prototyping on the line itself is done. Physical prototypes are run on certain sections in the line to see how it works, and to check if any improvements are to be made to the line. When a new model finally arrives, Hyundai is fully prepared to immediately integrate it.

From here, the panels move on to the next stop in the manufacturing process, the body shop. This is where the car begins to develop its final shape. The basic structure is put together here, with the doors, hood and boot being attached, too. Most of it is heavily automated and robotic arms carry out precision-based processes such as welding with great accuracy and efficiency. Technicians use machines to rivet in a few parts such as the hood and boot, and at the end what remains is a complete shell of the Creta. Of course, it is missing all internals, but the external shape is complete. At this point, the Creta models equipped with the panoramic sunroof are sent for further processing. The panoramic sunroof in the Creta is unique in that it is fixed to the car from inside the car. This process allows for better tolerances on the sunroof and increases its serviceability.

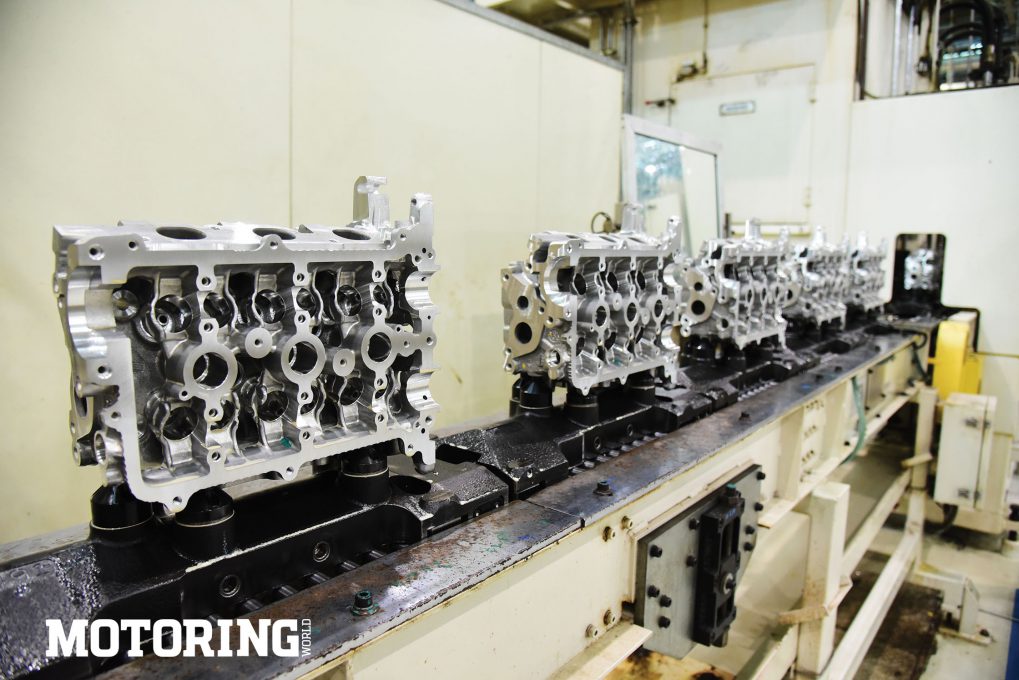

The percentage of high strength steel and advanced high strength steel in the All New Hyundai Creta has been increased to 74.3 per cent to improve structural rigidity and to keep weight down as well. As a result, the shell of the new Creta weighs a little under 300 kg while still maintaining superb rigidity and strength. The body in white of the Creta is then taken to the testing area where, with the help of 3D scanning robots, all the panels and welds are inspected to ensure they meet the specified tolerances.

The body moves on to the state-of-the-art paint shop after all the fittings are installed. This is another step in the manufacturing process that requires little to no human involvement. The All New Hyundai Creta is available in 10 colours including two dual-tone colours on the Turbo Pack.

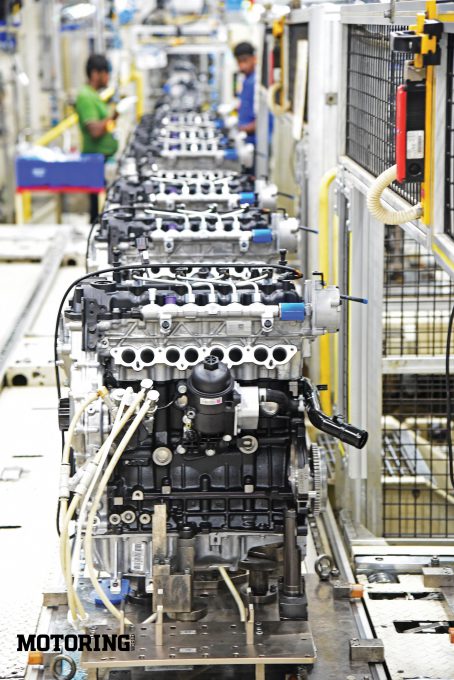

After the paint shop, the body finally reaches the assembly line. This is the most critical part of the manufacturing process as it is where the entire car is finally put together and given life. Initially, the doors are removed to make it easier to access the inside and the interiors are first installed by hand using machines for lifting the heavy parts. Seats are installed next along with the electricals. All the parts and fittings required to assemble the specific model and trim are readily available on carts placed parallel to the assembly line. Once the interior of the car is put together, it’s time to move on to one of the most important steps in the manufacture of a vehicle — the marriage between the powertrain and the body.

The body arrives on a separate line above, while the powertrain is on a line below and they meet in perfect harmony. Technicians expertly bolt them together, along with the suspension and brakes before finally fixing the wheels to the Creta. This is the final stage, before fluids are put into the completed car and it is cranked for the very first time. Of course, the new car starts effortlessly. It is finally alive!

The newborn Creta is then driven to the rolling road where the engine and transmission are tested in a controlled environment. There is also a leak-test area where the entire car is subjected to extreme wet-weather testing to ensure that the car is properly weather sealed. Finally, it’s off to the test track next door where all cars are put through their paces, post which they are lined up once again for a final inspection. Every inch of the car is carefully looked over — even the paint job is inspected for uniformity. Only when it passes all inspections does it move the final stop in the manufacturing facility — the transport bay. Here row upon row of trailers wait in line to be loaded up with cars. Once packed, they head straight to dealers and distributors, who give it one last pre-delivery inspection. Eager customers finally get their hands on their prized possessions.

It takes a lot to convert sheet metal into the All New Hyundai Creta, and while the final product is already poised to take the market by storm, it is all possible because of the symphony of technicians and machines working like clockwork!