The popular show Mythbusters, a staple of the late 2000s and early 2010s, captivated audiences with its team of five science enthusiasts dedicated to debunking myths and legends. One particularly fascinating myth they explored revolved around the aerodynamic efficiency of golf balls.

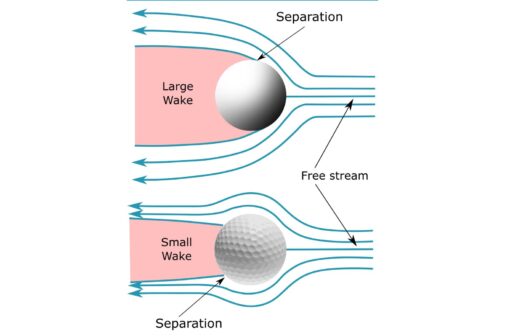

The myth in question was whether the dimpled design of a golf ball, renowned for its aerodynamic efficiency, really did make for an efficient aerodynamic design. The science behind golf ball dimples is intriguing: these tiny indentations help reduce drag by creating a turbulent boundary layer of air around the ball. This turbulent layer delays airflow separation from the ball’s surface, resulting in a smaller wake and reduced drag. Consequently, a golf ball can travel farther due to this enhanced aerodynamic performance.

To put this myth to the test, the Mythbusters team crafted a clay model of a car covered in dimples, mimicking the surface of a golf ball. When they placed this dimpled car in a wind tunnel, the results were remarkable. The team observed a nearly 14 per cent increase in aerodynamic efficiency. This significant improvement demonstrated the potential benefits of applying dimple technology to car surfaces.

Despite the promising results, we don’t see dimpled cars on the road. The primary reason is that cars need to balance aerodynamic efficiency with other critical factors, such as cooling. Cars rely on manipulating airflow to cool vital components like engines and brakes. This necessity complicates the straightforward application of dimples to car designs. Imagine Formula One cars or MotoGP bikes with dimpled bodies—not only would it be an unusual sight, but it might also hinder their performance by disrupting essential cooling mechanisms.

Nonetheless, the exploration of such myths provides valuable insights into the innovative possibilities within automotive design.